COMPLETION REPORT 21ST AUGUST, 2020

SOLIDEDGE Project Managers : Operations and project team

Project Schedule Update

Start date site 1 : 18th July , 2020

Planned completion : 20th August, 2020

% Project completion : 100%

DISCLAIMER WARNING: This project was managed and supervised by SOLIDEDGE Facilities 100%, no third Party involved. SEFM self performs all its projects.

Issues / Risks Identified

| There was Stop work order from LAGOS Local Government for payment of Development levy and Renovation permit fee of NGN 450,000.00 which SOLIDEDGE Facilities paid agreed amount on behalf of MANTRAC. Other extortions from local council boys were recorded here and Nigerian Police force presence maintained law and order as work progressed. |

| Tools box talk remain our first assignment before commencement of each days task. No accident or incident that would cause injury or death recorded throughout the project work. Safety first was observed. |

MANTRAC CAT NIGERIA BOUNDARY FENCE WALL SCOPE COVERED TO COMPLETION

| JOB ID | TASK DESCRIPTION | % Completion | Status |

| M000 | Mobilization to site | 100 | Completed |

| CST001 | Setting out and site hoarding | 100 | Completed |

| RAR002 | Trench foundation to prepare for footing and ground beam | 100 | completed |

| RRW003 | Prepared formwork for the footing and beam | 100 | completed |

| INA004 | Arranged for pre-casting of the footing reinforcement | 100 | completed |

| POP005 | Applied blinding of the foundation to get footing toe | 100 | completed |

| REF006 | Placed the reinforcement for ground beam and matting of footing | 100 | completed |

| RPF007 | Formation of formwork for the footing and ground beam | 100 | completed |

| KC008 | Casting of footing | 100 | completed |

| FAP009 | Casting of ground beam and set the column with controlled height | 100 | completed |

| EF010 | Placing form work for the columns and cast | 100 | completed |

| MD011 | Allow for the erection of block walls to make up fence wall of 3,2m | 100 | completed |

| FSD012 | Cast pillars/column for the fence wall reinforcement | 100 | completed |

| BWR013 | Prepare formwork for capping and copping | 100 | completed |

| IDH014 | Casting of copping and placement of reinforcement for the copping | 100 | completed |

| IWH015 | Applied the security wire y-set for the installation | 100 | completed |

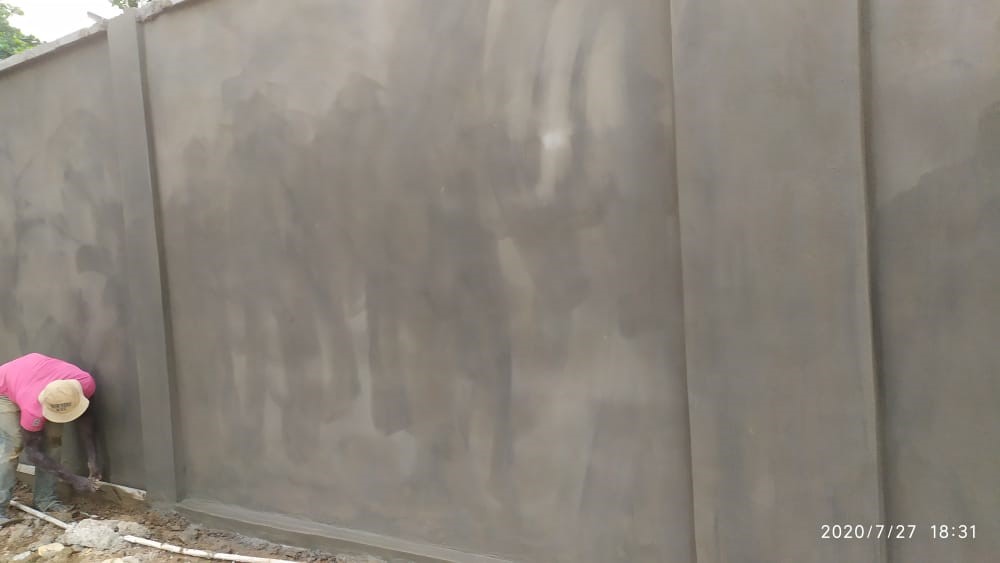

| PIE016 | Plastered the walls inside and outside and rendered cement screed | 100 | completed |

| RIE017 | Removed all wall formations and backfill | 100 | completed |

| RIKB018 | Install security barb wire and demobilize site | 100 | completed |

| EW022 | Evacuation of all waste and other construction waste | 100 | completed |

Foundation blinding

Foundation footing matting and beam starter

Showing reinforced pillars/columns

Showing Expansion joints Pillars/Columns at 5 span

Plastering of wall

Plastered wall with expansion joint

Completed both sides of the MNTRAC CAT boundary fence wall of 16457.78SQ,Mters

Completed both sides of the MNTRAC CAT boundary fence wall of 16457.78SQ,Mters

Column dressing accuracy check

Fence wall stretch of over 480 meters or 1440 ft long